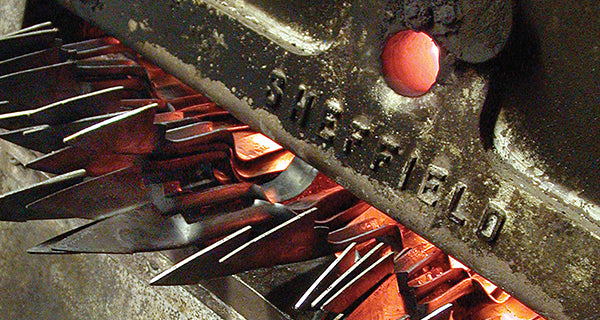

Steel Making Expertise

We’ve been working with steel for a long time: since 1730, in fact. We know how to get the best out of the material and how to create tools of exceptional quality.

We make our tools with seven principles in mind. Read on to learn more.

Adding carbon to steel gives strength, adding chromium brings rust resistance. But it’s a trade-off; our steel cannot be high carbon and high chromium, so we make sure we get the right steel composition for each part of the tool.

A single hand fork contains three different compositions of steel:

-

1Ferrule

High chromium/low carbon. Why? It starts life as a disc, so we don’t want this to be too hard because we want to shape it. It doesn’t need strength for its end function. -

2Tang

Medium chromium/medium carbon. Why? It needs to be strong to resist bending, but is also made from quite thick material to give good levels of inherent strength. -

3Tines

Low chromium/maximal carbon. Why? Tines are the weakest part of the tool, yet need maximum strength and hardness to resist bending in the ground.

But we don’t stop there. Rigorous testing gives complete peace of mind; every batch of tools is tested against the British Standard, which determines the weight the tools must be able to withstand without permanent deformation.

And if ever a batch were to fail… we wouldn’t sell it.